Experimentation toward creating a man-made fiber out of tree pulp dates to around 1860, but only in 1894 was the production of the fiber cellulosic acetate patented—by Arthur D. Little of Boston. It was the second manufactured cellulosic fiber, following rayon, and it was used for film, celluloid plastic and “artificial silk” (as both rayon and acetate were called at that time). The brothers Camille and Henri Dreyfus of Switzerland were the first to develop a satisfactory process for commercially producing the fiber in 1905.

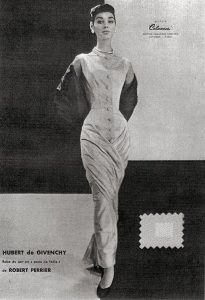

Acetate was first made commercially in England after World War I, by British Celanese Limited, calling its fiber celanese. The fiber was first spun commercially in the U.S. in 1924, and it was trademarked as Celanese.

Acetate was given a grouping separate from rayon by the U.S. Federal Trade Commission in 1953. Acetate is manufactured under many trade names, including Celanese, Acele, and Estron in the U.S., and Dicel and Lansil in the U.K.

Unlike rayon, which also starts with cellulose from wood pulp, the making of acetate employs the use of acetic acid or acetic anhydride. The resulting liquid can be dyed brilliant colors, then spun. The finished fiber is silk’s closest man-made competitor for drape and sheen.

See also

Rayon, viscose

Triacetate